Freeze Dried Camel Milk Powder

Compared with the traditional spray drying process of milk powder, the processing of milk powder by freeze-drying technology can not only preserve the physiological activity of functional components in milk, but also help to maintain the color, aroma, taste and nutritional components, and facilitate storage and transportation. It has been recognized and popular in the infant food market. At present, the application of freeze-drying technology in dairy products is still expanding, such as horse milk freeze-drying, bovine colostrum freeze-drying, camel milk freeze-drying, donkey milk freeze-drying and so on.

Compared with the traditional spray drying process of milk powder, the processing of milk powder by freeze-drying technology can not only preserve the physiological activity of functional components in milk, but also help to maintain the color, aroma, taste and nutritional components, and facilitate storage and transportation. It has been recognized and popular in the infant food market. At present, the application of freeze-drying technology in dairy products is still expanding, such as horse milk freeze-drying, bovine colostrum freeze-drying, camel milk freeze-drying, donkey milk freeze-drying and so on.

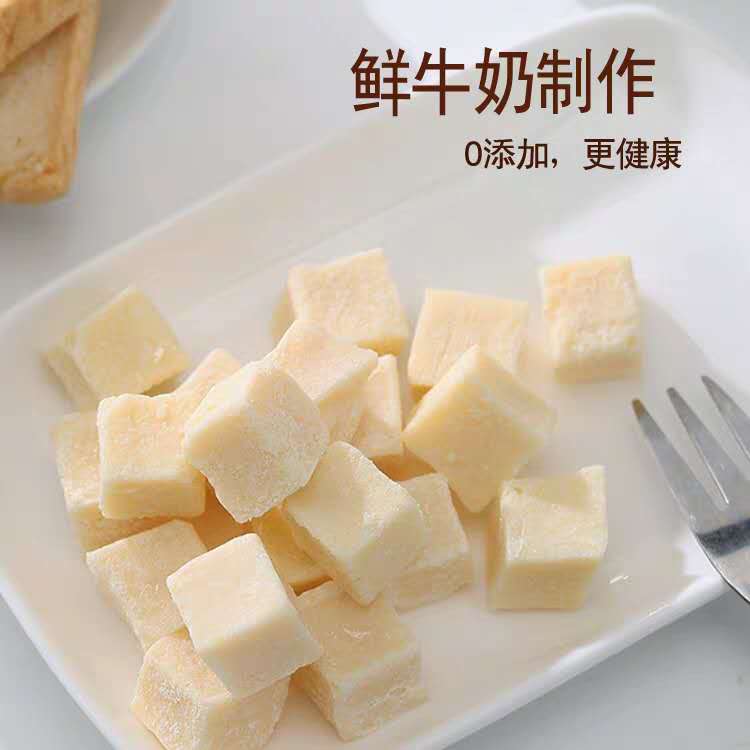

At present, the freeze-drying machine is applied in the field of milk. In addition to the freeze-drying of milk powder, manufacturers also pay attention to the field of baby food and children's snacks. In the foreign freeze-dried food market, the freeze-dried milk block has the advantages of sufficient flavor, high nutrition, easy to carry, and a cup of milk after brewing. It is deeply loved by people. Moreover, the freeze-dried milk block has a crisp structure and good taste, which solves the problem of sticking teeth in traditional milk tablets and greatly avoids the hidden danger of children sticking to their throats when eating milk tablets.

The following is a brief summary of the milk lyophilization process and the lyophilized milk block lyophilization process:

1. Raw materials: infant formula (the user can choose according to the product itself, or it can be fresh milk), freeze-drying equipment: new food freeze-drying machine equipment;

2. When the milk powder is mixed, various auxiliary materials such as microorganisms and trace elements required by the milk powder can also be added.

3. Pour the milk prepared in step 2 into the food silica gel mold, freeze it at low temperature, then demould it, and place it into the stainless steel tray of the freeze-drying machine;

4. Put the tray into the freeze-drying bin of the yogurt block freeze-drying equipment for vacuum freeze-drying (for the milk freeze-drying process, the red deer freeze-drying machine manufacturer will set it up with the equipment and pass the coaching and training);

5. When the automatic operation of the milk freeze-drying program is completed, the dehydrated solid freeze-dried milk pieces can be obtained and stored in sealed packaging# Lyophilizer manufacturer

Related Products

Submitted successfully

We will contact you as soon as possible